JPI7S-15-99 Bridas Clase 300

La brida es un tipo de pieza de conexión que puede conectar tuberías, válvulas y equipos. Las ventajas de las bridas incluyen: 1. Buena flexibilidad: la conexión de la brida es fácil de desarmar y ajustar, lo cual es conveniente para el mantenimiento y reemplazo del equipo. 2. Buen sellado: las juntas de brida pueden usar diferentes juntas o juntas para cumplir con los diferentes requisitos de presión y fluidos, y tener un buen sellado. 3. Gran capacidad de carga de presión: las juntas de brida pueden soportar grandes presiones internas y externas, lo que las hace adecuadas para entornos de trabajo duros como alta temperatura, alta presión y corrosión. 4. Alta confiabilidad: dado que la conexión de brida está conectada por pernos y tuercas, puede garantizar la firmeza de la conexión, lo que mejora la estabilidad y confiabilidad de los equipos y tuberías. 5. Gran adaptabilidad: las juntas de brida se pueden seleccionar de una variedad de materiales, tamaños y especificaciones según las necesidades, y se pueden adaptar a diversos entornos y requisitos de trabajo.

The JPI7S-15-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

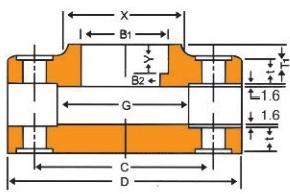

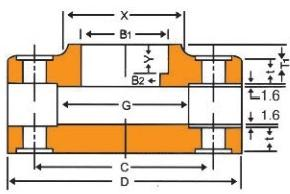

Nominal Tubo Tamaño |

afuera de Bridas |

Diámetro de diámetro |

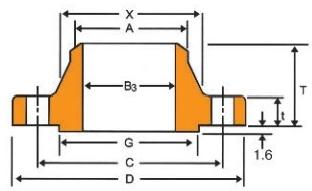

Diámetro del cubo en bisel A |

Dia.of Hub en Base |

de Aumentó Rostro |

Grueso de Bridas |

Radio de Filete |

|||||||||||

Ponerse Zócalo B1 |

Junta de solape B2 |

Cuello de soldadura, zócalo B₃ |

||||||||||||||||

JPI |

ANSI |

|||||||||||||||||

A |

B |

D |

JPI |

ANSI |

JPI |

ANSI |

SCH40 |

SCH80 |

SCH160 |

SCH40 |

SCH80 |

SCH160 |

JPI |

ANSI |

X |

GRAMO |

t |

R |

15 20 25 |

h % 1 |

95 117 124 |

22.2 27.7 34.5 |

22.4 27.7 34.6 |

23,4 28,9 35.6 |

22,9 28,2 35.1 |

16,1 21,4 27.2 |

14,3 19,4 25,0 |

12,3 16,2 21.2 |

15,8 20,9 26.6 |

13,9 18,8 24.3 |

11,8 15,6 20.7 |

21,7 27,2 34,0 |

21,3 26,7 33.5 |

38,1 47,8 53.8 |

35,1 42,9 50.8 |

14,2 15,7 17.5 |

3 3 3 |

(32) 40 50 |

(14) 1% 2 |

133 155 165 |

43.2 49.1 61.1 |

43.2 49.6 62.0 |

44,3 50,4 62.7 |

43,7 50,0 62.5 |

35,5 41,2 52.7 |

32,9 38,4 49.5 |

29,9 34,4 43.1 |

35,1 40,9 52.5 |

32,5 38,1 49.3 |

29,5 34,0 42,9 |

42,7 48,6 60.5 |

42,2 48,3 60.5 |

63,5 69,9 84.1 |

63,5 73,2 91,9 |

19,1 20,6 22.4 |

5 6 8 |

sesenta y cinco 80 (90) |

2% 3 (3%) |

190 210 229 |

77,1 90,0 102.6 |

74,7 90,7 103.4 |

78,7 91,6 104.1 |

75,5 91,4 104.2 |

65,9 78,1 90.2 |

62,3 73,9 85.4 |

57,3 66,9 76.2 |

62,7 77,9 90.1 |

59,0 73,7 85.5 |

54.0 66.7 |

76,3 89,1 101.6 |

73,2 88,9 101.6 |

100,1 117,5 133.4 |

104,6 127,0 139.7 |

25,4 28,4 30.2 |

8 10 10 |

100 (125) 150 |

4 (5) 6 |

254 279 318 |

115,4 141,2 166.6 |

116,1 143,8 170.7 |

116,9 143,0 168.4 |

116,9 144,6 171.5 |

102,3 126,6 151.0 |

97,1 120,8 143.2 |

87,3 108,0 128.8 |

102,3 118,2 154.2 |

97,2 122,3 146.3 |

87,3 109,6 131.8 |

114,3 139,8 165.2 |

114,3 141,2 168.4 |

146,1 177,8 206.2 |

157,2 185,7 215.9 |

31,8 35,1 36.6 |

11 11 13 |

200 250 300 |

8 10 12 |

381 444 521 |

218,0 269,5 321.0 |

221,5 276,4 327.2 |

219,5 271,7 322.8 |

222,3 277,4 328.2 |

199,9 248,8 297.9 |

190,9 237,2 283.7 |

170,3 210,2 251.9 |

202,7 254,5 303.2 |

193,7 242,9 288.9 |

173,1 215,9 257.2 |

216,3 267,4 318.5 |

219,2 273,1 323.9 |

260,4 320,8 374.7 |

269.7 323.9 381.0 |

41.1 47.8 50.8 |

13 13 13 |

350 400 450 |

14 dieciséis 18 |

584 648 710 |

358,1 409,0 460.0 |

359,2 410,5 461.8 |

360,2 411,3 462.4 |

333,4 381,0 428.6 |

317,6 363,6 409.6 |

284,2 325,4 366.8 |

333,3 381,0 428.7 |

317,5 363,6 409.6 |

284,2 325,5 366.7 |

355,6 406,4 457.2 |

355,6 406,4 457.2 |

425.5 482.6 533.4 |

412,8 469,9 533.4 |

53,8 57,2 60.5 |

13 13 13 |

|

500 600 |

20 veinticuatro |

775 914 |

511.0 613.0 |

513.1 616.9 |

514.4 616.0 |

477.8 574.6 |

455.6 547.8 |

408.0 490.6 |

477.8 574.8 |

455.6 547.7 |

408.0 490.6 |

508.0 609.6 |

508.0 609.6 |

587.2 701.5 |

584.2 692.2 |

63.5 69,9 |

13 13 |

|

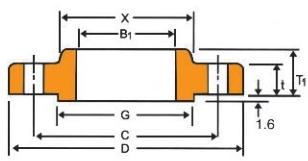

Longitud a través del cubo |

Profundidad de Enchufe |

Perforación |

diapositiva de Aumentó Cara para Anillo Sello |

Paso de diámetro o anillo & Ranura |

Anillo

De. |

Tipo RTJ |

Peso aproximado (kg) |

Nominal Tubo Tamaño |

||||||||||

Rosca de enchufe deslizante |

Regazo

Sello |

Soldadura Cuello |

Dia of Bolt Circle |

Número de Almacenar |

Diámetro del perno Agujero |

Profundidad de Ranura |

Ancho de Surco |

radio de Ranura |

W.N |

S.0 |

S.W |

licenciado en Derecho |

||||||

T; |

T2 |

T |

Y |

C |

N |

K(mín) |

P |

Y |

F |

4 |

A |

B |

||||||

22.2 25,4 27.0 |

22.2 25.4 27.0 |

52.4 57.2 61.9 |

9.5 11.1 12.7 |

66.5 82.6 88.9 |

4 4 4 |

16 19 19 |

51.0 63.5 70.0 |

34.14 42.88 50.80 |

R11 R13 R16 |

5.56 6.35 6.35 |

7.14 8.74 8.74 |

0.8 0.8 0.8 |

0.80 1.25 1.58 |

0.65 1.10 1.35 |

0.67 1.12 1.39 |

0.65 1.09 1.38 |

15 20 25 |

C % 1 |

27.0 30.2 33.3 |

27.0 30.2 33.3 |

65.1 68.3 69.8 |

14.3 15.9 17.5 |

98.6 114.3 127.0 |

4 4 8 |

19 22 19 |

79.5 90.5 108 |

60.32 68.28 82.55 |

R18 R20 R23 |

6.35 6.35 7.92 |

8.74 8.74 11.91 |

0.8 0.8 0.8 |

2.05 2.93 3.40 |

1.69 2.54 2.92 |

1.74 2.60 3.02 |

1.82 2.70 3.18 |

(32) 40 50 |

(114) (1 es.) 2 |

38.1 42.9 44.5 |

38.1 43.9 44.5 |

76.2 79.4 81.0 |

19.0 20.6 22.2 |

149.4 168.1 184.2 |

8 8 8 |

22 22 22 |

127 146 159 |

101.60 123.82 131.78 |

R26 R31 R34 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

5.10 7.01 8.71 |

4,24 5,94 7.90 |

4.43 6.21 |

4,86 6,90 8.79 |

65 80 (90) |

2% 3 (3%) |

47.6 50.8 52.4 |

47.6 50.8 52.4 |

85.7 98.4 98.4 |

23.8 23.8 27.0 |

200,2 235,0 269.7 |

8 8 12 |

22 22 22 |

175 210 241 |

149.22 180.98 211.12 |

R37 R41 R45 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

11,3 15,1 19.6 |

9.71 12.4 16.2 |

11,6 15,5 21.2 |

100 (125) 150 |

4 (5) 6 |

|

61,9 66.7 73.0 |

61.9 95.3 101.6 |

111,1 117,5 130.2 |

31,8 33,3 39.7 |

330,2 387,3 450.9 |

12 16 16 |

26 29 32 |

302 356 413 |

269.88 323.85 381.00 |

R49 R53 R57 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

30,3 44,3 64.1 |

24.8 35,9 51 |

34.5 53.9 78.9 |

200 250 300 |

8 10 12 |

|

76.2 82.6 89.9 |

※111.3 ※120.7 ※130.0 |

142,9 146,0 158.8 |

41,3 44,5 49.2 |

514.4 571.5 628.7 |

20 20 veinticuatro |

32 35 35 |

457 508 575 |

419.10 469.90 533.40 |

R61 R65 R69 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

88.3 113 138 |

70,1 90,4 109 |

106 139 175 |

350 400 450 |

14 dieciséis 18 |

|

95.2 106.4 |

※149.7 ※152.4 |

161.9 168.3 |

54.0 63.5 |

685.8 812.8 |

.veinticuatro veinticuatro |

35 42 |

635 749 |

584.20 692.15 |

R73 R77 |

9.52 11.13 |

13.49 16.66 |

1.5 1.5 |

169 248 |

136 204 |

222 340 |

500 600 |

20 veinticuatro |

|

Nuestra fábrica

Supresión de materia prima

examen de laboratorio

Forja y forja y prensado

Procesamiento de máquinas

Honor de calificación empresarial