The JPI7S-15-99 Class one hundred fifty flanges have numerous blessings and wonderful characteristics. Here are some of them:

Pressure rating: These flanges have a stress ranking of Class 150, which capability they can face up to a most stress of one hundred fifty kilos per rectangular inch.

Size range: The flanges are accessible in a vast vary of sizes, normally from half inch to 24 inches, making them appropriate for a number piping systems.

Piping compatibility: The Class one hundred fifty flanges are well suited with pipes of distinctive materials, such as carbon steel, stainless steel, and alloy steel, presenting versatility in application.

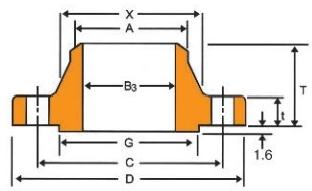

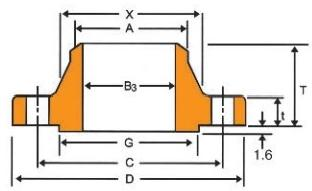

Flange face type: The JPI7S-15-99 flanges have a raised face (RF) design. This graph ensures appropriate sealing and prevents leakage, making them appropriate for functions that contain high-pressure fluids.

Production process: The JPI7S-15-99 Class a hundred and fifty flanges are normally manufactured the usage of the following manufacturing process:

a. Material selection: The flanges are made from tremendous materials, such as solid carbon metal or stainless steel, making sure electricity and durability.

b. Raw cloth preparation: The chosen cloth is reduce into fabulous sizes and shapes, and any floor imperfections are removed.

c. Heating and forging: The organized cloth is heated to a particular temperature and then cast the usage of mechanical or hydraulic presses. This manner ensures the required dimensions and electricity of the flange.

d. Machining: After forging, the flange undergoes machining operations to reap specific dimensions and a easy floor finish. This consists of operations like drilling bolt holes, tapping threads, and dealing with the flange.

e. Inspection and testing: Once machining is complete, the flanges bear thorough inspection and trying out to make certain they meet the required requirements and specifications. This consists of dimensional checks, visible inspections, and assessments for strain resistance and leakage.

f. Surface treatment: Depending on the utility requirements, the flanges may additionally bear floor remedies like portray or galvanizing to decorate corrosion resistance.

g. Packaging and delivery: The performed flanges are packed securely, frequently in wood crates or pallets, to make certain secure transportation and storage till they attain the customers.

Overall, the JPI7S-15-99 Class a hundred and fifty flanges provide dependable and environment friendly connections in more than a few piping systems, thanks to their particular design, cloth selection, and well-defined manufacturing process.

Nominal Tubo Tamaño |

Fuera de Dia.of Bridas |

Diámetro de diámetro |

Diámetro del cubo en bisel A |

de Llama a Base |

Dia.de levantado Rostro |

Grueso de Bridas |

Radio de Filete |

|||||||||||

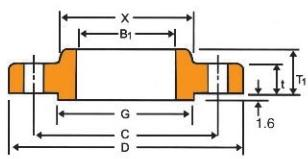

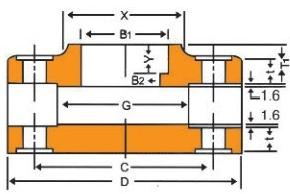

Ponerse Zócalo B1 |

Junta de solape B2 |

Soldadura-cuello, enchufe B3 |

||||||||||||||||

JPI |

ANSI |

|||||||||||||||||

A |

B |

D |

JPI |

ANSI |

JPI |

ANSI |

SCH40 |

SCH80 |

SCH160 |

SCH40 |

SCH80 |

SCH160 |

JPI |

ANSI |

X |

GRAMO |

t |

R |

15 20 25 |

% % 1 |

89 98 108 |

22,2 27,7 34.5 |

22,4 27,7 34.6 |

23.4 28,9 35.6 |

22,9 28.2 35.1 |

16,1 21,4 27.2 |

14,3 19,4 25,0 |

12,3 16,2 21.2 |

15,8 20,9 26.6 |

13.9 18.8 24.3 |

11,8 15,6 20.7 |

21,7 27,2 34,0 |

21,3 26,7 33.5 |

30,2 38,1 49.3 |

35.1 42,9 50.8 |

11.2 12.7 14.3 |

3 3 3 |

(32) 40 50 |

(174) 1% 2 |

117 127 152 |

43,2 49,1 61.1 |

43,2 49,6 62.0 |

44.3 50.4 62.7 |

43.7 50.0 62.5 |

35,5 41,2 52.7 |

32,9 38,4 49.5 |

29,9 34,4 43.1 |

35,1 40,9 52.5 |

32.5 38.1 49.3 |

29,5 34,0 42,9 |

42,7 48,6 60.5 |

42,2 48,3 60.5 |

58,7 65,0 77.6 |

63,5 73,2 91,9 |

15.0 17.5 19.1 |

5 6 8 |

sesenta y cinco 80 (90) |

2% 3 3 |

178 190 216 |

71,1 90,0 102.6 |

74,7 90,7 103.4 |

78,7 91,6 104.1 |

75,5 91,4 104.2 |

65,9 78,1 90.2 |

62,3 73,9 85.4 |

57,3 66,9 76.2 |

62,7 77,9 90.1 |

59.0 73.7 85.5 |

54.0 66.7 |

76,3 89,1 101.6 |

73,2 88,9 101.6 |

90,4 108,9 122.2 |

104,6 127,0 139.7 |

22.3 23,9 23,9 |

8 10 10 |

100 (125) 150 |

4 (5) 6 |

229 254 279 |

115,4 141,2 166.6 |

116,1 143,8 170.7 |

116,9 143,0 168.4 |

116,9 144,6 171.5 |

102,3 126,6 151.0 |

97,1 130,8 143.2 |

87,3 108,0 128.8 |

102,3 118,2 154.2 |

97,2 122,3 146.3 |

87,3 109,6 131.8 |

114,3 139,8 165.2 |

114,3 141,2 168.4 |

134,9 163,6 192.0 |

157,2 185,7 215.9 |

23,9 23,9 25.4 |

11 11 13 |

200 250 300 |

8 10 12 |

343 406 483 |

218,0 269,5 321.0 |

221,5 276,4 327.2 |

219,5 271,7 322.8 |

222,3 277,4 328.2 |

199,9 248,8 297.9 |

190,9 237,2 283.7 |

170,3 210,2 251.9 |

202.7 254.5 303.2 |

193,7 242,9 288.9 |

173,1 215,9 257.2 |

216,3 267,4 318.5 |

219,2 273,1 323.9 |

246,1 304,8 365.3 |

269.7 323.9 381.0 |

28.6 30.2 31.8 |

13 13 13 |

350 400 450 |

14 dieciséis 18 |

533 597 635 |

358,1 409,0 460.0 |

359,2 410,5 461.8 |

360,2 411,3 462.4 |

333,4 381,0 428.6 |

317,6 363,6 409.6 |

284,2 325,4 366.8 |

333,3 381,0 428.7 |

317,5 363,6 409.6 |

284,2 325,5 366.7 |

355,6 406,4 457.2 |

355,6 406,4 457.2 |

400.1 457.2 505.0 |

412,8 469,9 533.4 |

35,0 36.6 39.7 |

13 13 13 |

|

500 600 |

20 veinticuatro |

698 813 |

511.0 613.0 |

513.1 616.0 |

514.4 616.0 |

477.8 574.6 |

455.6 547.8 |

408.0 490.6 |

477.8 574.8 |

455.6 547.7 |

408.0 490.6 |

508.0 609.6 |

508.0 609.6 |

558.8 663.4 |

584.2 692.2 |

42,9 47.7 |

13 13 |

|

Longitud a través del cubo |

Profundidad de Enchufe |

Perforación |

Dia de levantado Cara para Anillo Articulación |

Paso de diámetro o anillo & Ranura |

Anillo

De. |

Tipo RTJ |

Peso aproximado (kg) |

Nominal Tubo Tamaño |

||||||||||

Zócalo deslizable Hilo |

Regazo Sello |

Soldadura Cuello |

Dia of Bolt Circle |

Número de Almacenar |

Diámetro del perno Agujero |

Profundidad de Ranura |

Ancho de Surco |

radio de Ranura |

W.N |

S.0 |

S.W |

licenciado en Derecho |

||||||

|

T2 |

T |

Y |

C |

N |

K(mín) |

P |

Y |

F |

5 |

A |

B |

||||||

15,9 15,9 17.5 |

15.9 15.9 17.5 |

47,6 52,4 55,6 |

9.5 11.1 12.7 |

60,5 70,0 79.5 |

4 4 4 |

dieciséis dieciséis dieciséis |

63.5 |

47.62 |

R15 |

6.35 |

8.74 |

0.8 |

0,50 0,75 1.02 |

0,41 0,57 0.78 |

0,42 0,58 0.80 |

0,43 0,62 0.87 |

15 20 25 |

% 1 |

20,6 22,2 25.4 |

20,6 22,2 25.4 |

57,2 61,9 63.5 |

14.3 15.9 17.5 |

89,0 98,5 120.5 |

4 4 4 |

dieciséis dieciséis 19 |

73.0 82.5 102 |

57,15 69,07 82.55 |

R17 R19 R22 |

6.35 6.35 6.35 |

8.74 8.74 8.74 |

0.8 0.8 0.8 |

1,33 1,72 2.59 |

1,03 1,32 2.09 |

1,06 1,35 2.13 |

1,16 1,54 2.46 |

(32) 40 50 |

(14) (1%) 2 |

28,6 30,2 31.8 |

28,6 30,2 31.8 |

69,8 69,8 71.4 |

19.0 20.6 22.2 |

139,5 152,5 178.0 |

4 4 8 |

19 19 19 |

121 133 154 |

101.60 114.30 131.78 |

R25 R29 R33 |

6.35 6.35 6.35 |

8.74 8.74 8.74 |

0.8 0.8 0.8 |

4,06 4,95 6.08 |

3,25 3,91 4.86 |

3.35 4.02 |

3,99 4,98 6.20 |

65 80 (90) |

2% 3 (32) |

33,3 36,5 39.7 |

33,3 36,5 39.7 |

76,2 88,9 88,9 |

23.8 23.8 27.0 |

190,5 216,0 241.5 |

8 8 8 |

19 Veintidós Veintidós |

171 194 219 |

149.22 171.45 193.68 |

R36 R40 R43 |

6.35 6.35 6.35 |

8.74 8.74 8.74 |

0.8 0.8 0.8 |

6,91 8,75 10.8 |

5,35 6,22 7.76 |

7,05 8,67 11.3 |

100 (125) 150 |

4 (5) 6 |

|

44,4 49,2 55,6 |

44,4 49,2 55,6 |

101.6 101.6 114.3 |

31,8 33,3 39.7 |

298,5 362,0 432.0 |

8 12 12 |

Veintidós 25 25 |

273 330 406 |

274,65 304,80 381.00 |

R48 R52 R56 |

6.35 6.35 6.35 |

8.74 8.74 8.74 |

0.8 0.8 0.8 |

18,0 24,9 38.6 |

12,6 17,6 27.8 |

19,9 29,0 43.7 |

200 250 300 |

8 10 12 |

|

57,2 63,5 68.3 |

※79.3 ※87.4 ※96.8 |

127,0 127,0 139.7 |

41,3 44,5 49.2 |

476,0 539,5 578.0 |

12 16 16 |

29 29 32 |

425 483 546 |

396.88 454.02 517.52 |

R59 R64 R68 |

6.35 6.35 6.35 |

8.74 8.74 8.74 |

0.8 0.8 0.8 |

50,6 63,9 74,9 |

35,2 45,3 49.7 |

58,6 76,6 94.5 |

350 400 450 |

14 dieciséis 18 |

|

73.0 82.6 |

※103.1 ※111.3 |

144.5 152.4 |

54.0 63.5 |

635.0 749.5 |

20 20 |

32 35 |

597 711 |

558.80 673.10 |

R72 R76 |

6.35 6.35 |

8.74 8.74 |

0.8 0.8 |

93.5 133 |

63.5 90.5 |

123 188 |

500 600 |

20 veinticuatro |

|

Nuestra fábrica

Supresión de materia prima

examen de laboratorio

Forja y forja y prensado

Procesamiento de máquinas

Honor de calificación empresarial